Molybdenum Plate

1. Brand: XZY

2. Catalog: Molybdenum product

3. Material: Pure molybdenum, MoLa alloy, TZM alloy, MoW alloy

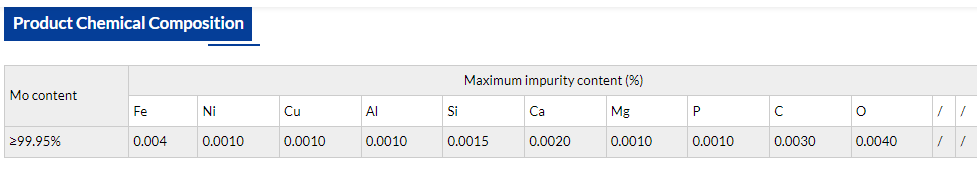

4. Molybdenum purity: 99.95% min

5. Density: 10.2g/cm3

6. Surface: Cold rolled, hot rolled, alkali washed surface, polished surface, ground surface

7. Processing method: powder metallurgy, sintering, rolling

8. Standard: GB/T 3876-2017, ASTM B386

Product Feature And Application

1) Feature

Molybdenum plate is a metal material with excellent performance.

It has a high melting point and thermal conductivity, so it has good high temperature resistance.

It also has good corrosion resistance.

Its mechanical performance is also very excellent. It has high strength and hardness, as well as good ductility and toughness.

2) Application

- Used for processing ion implantation parts

- Used for manufacturing electric light source parts, electric vacuum, electronic and semiconductor industry parts, molybdenum sputtering targets

- Used for making molybdenum boats, molybdenum containers, and molybdenum push plates for high-temperature furnaces

- Used for sapphire crystal growth furnace components

- Used for making molybdenum heat shield , heating elements, heater, reflective screens for vacuum furnaces

- Used for high-temperature heating belts and connectors

- Used for medical radiation protection

Our Advantages

1. Advanced production technology and rich experience ensure that the product has good performance.

Molybdenum plates can be vacuum annealed and leveled. The plates produced by our company are cross-rolled ,and strict attention is paid to the control of grain size during the rolling process. To achieve perfect internal organizational structure, density, grain size, pore size, and grain boundary shape and distribution of the material.

Therefore, our products have better bending and stamping performance.